- Category : PRODUCTS

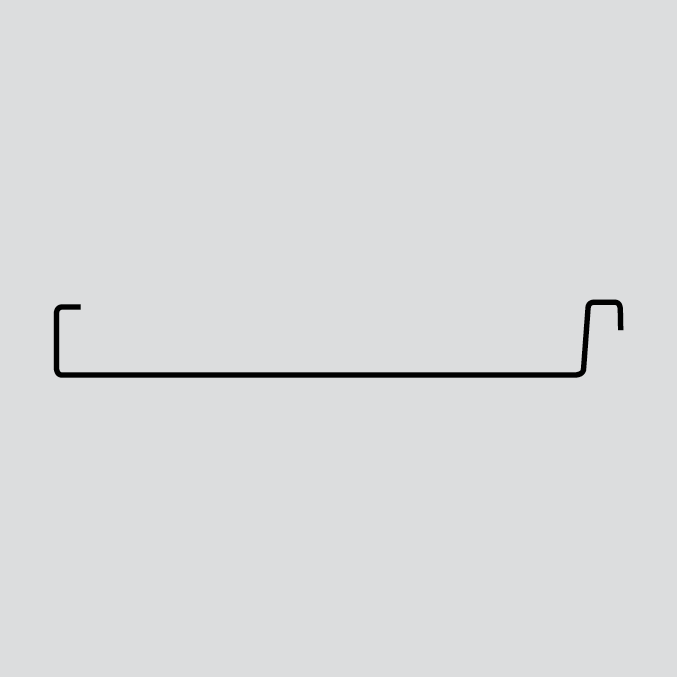

STANDING SEAM

Standing seam system is a traditional flat-tray roofing and cladding system with a raised 25mm seam. All fixings are concealed using stainless steel clips that allow for expansion and contraction in the cladding panels. The pan widths are customisable using our state of the art manufacturing equipment to the millimetre allowing total control over your designs. It reflects the individual concerns for both light and shadow and produces designs that have a modern yet historical perspective that offers a traditional, refined look, with maximum flexibility. Standing Seam is capable of achieving intricate designs that other systems cannot.

Standing seam is suitable for both roof (double-lock) and wall cladding (single-lock) which makes it ideal for dramatic residential and commercial architectural roofs and facades.

The single-lock Standing Seam can be installed vertically, horizontally or diagonally in wall cladding applications. Panels can be curved both horizontally and vertically. Seams can also be mitred into roofing pans for a seamless, flashing-less design. Many modern building designs now incorporate the single lock standing seam system.

The double-lock Standing Seam is a traditional system that has been used historically throughout Europe and America for many years. Seams can also be mitred into cladding pans for a seamless design. Many modern building designs now incorporate the double lock standing seam system.

OUR EXPERTISE

We work closely with architects during the design stages to share our expertise on installation and technical details. From traditional to contemporary applications, our aluminium, zinc and copper roofing and cladding solutions are specified based on their durable, sustainable and virtually maintenance-free nature that need to withstand the elements and protect those within. Being corrosion resistant, non-combustible, architecturally appealing, their outstanding list of benefits just can’t be beaten.

FEATURES & BENEFITS

- Incredible flexibility and versatility with standing seam metal roofing and cladding. Unlimited design options with panel widths changeable to suit wall and roof width, windows and skylight penetrations; tapered, curved, convex and concave; cross joints to create specific lines or continuous cladding for long panel applications.

- Fully waterproof with all details and panel connections made to leverage inherent material waterproofing.

- Economical due to minimal wastage of materials.

- Ability to connect with continuous seam to between single-lock standing seam wall cladding and double-lock standing seam roofing.

INSTALLATION

– 40mm continuous air gap must be beneath the plywood substrate for ventilation

– Breathable waterproofing membrane fixed to outer plywood substrate

– Single-lock Standing Seam cladding is installed on a minimum 15mm plywood substrate (‘other’ substrates are available for building with strict fire codes).

– Double-lock Standing Seam roofing is installed on a minimum 18mm plywood substrate (‘other’ substrates are available for building with strict fire codes)

– Concealed stainless steel clips and fasteners attached directly into plywood or other substrate.

DISCLAIMER

Metal cladding/roofing and especially lengthy flat-span sheet-metal panels often will exhibit waviness, commonly referred to as “oil-canning.” The degree of oil-canning and the appearance of the panels will vary depending on factors such as the length and colour of the panels, alloy, gauge, substrate condition and exposure to sunlight. Oil-canning pertains to aesthetics and not the performance of the panels and is not controlled by the contractor. The type of metal roofing panels specified can affect the degree of oil-canning. Roofing Group is not responsible for oil-canning or aesthetics. Oil-canning shall not be grounds to withhold payment or reject panels of the type specified. For more information please contact Roofing Group.