Faster installation as no requirement for automatic or manual seam closing making it a good choice for more standard applications in both roofing and wall cladding.

Flat appearance with no stress added to the panels, requiring no seams to close, and the panel is subjected to less oil canning (particularly with the use of zinc and copper roofing panels).

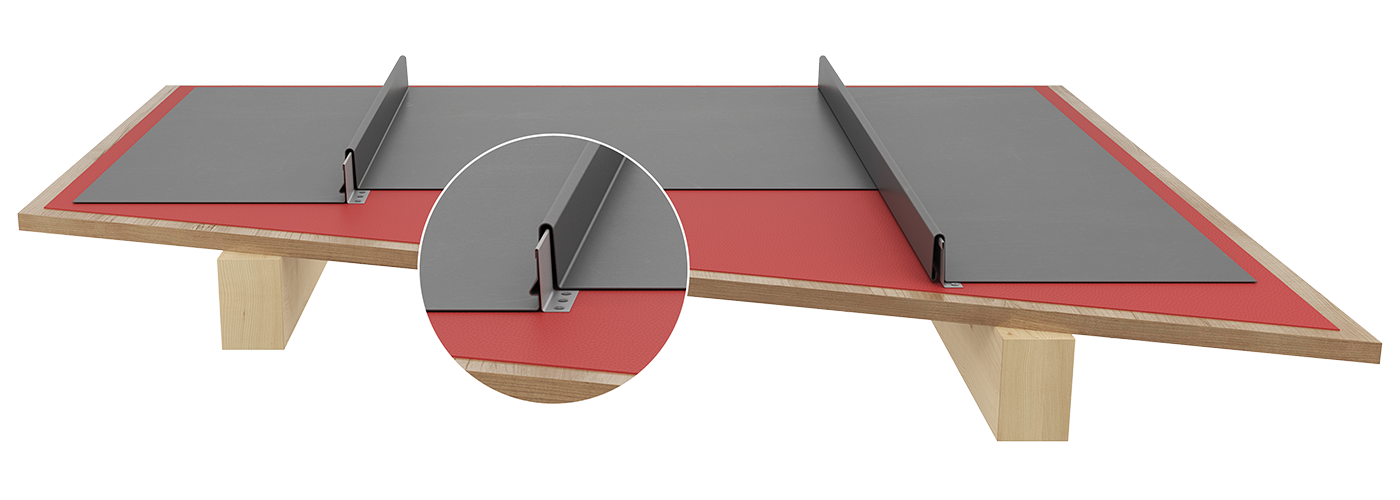

Snap lock roofing is similar in appearance to that of standing seam with a wide tray and a neutral raised seam.

Ability to adapt to lower pitched roofs with a 38mm seam height accepting pitch down to 1.5 degrees.

Ideal for very long panels as snap lock panel fixing details allows for more expansion and contractions.

Usable for both snap lock metal roofing & wall cladding and ability to connect with continuous seam.

We work closely with architects during the design stages to share our expertise on installation and technical details. From traditional to contemporary applications, our aluminium, zinc and copper roofing and cladding solutions are specified based on their durable, sustainable and virtually maintenance-free nature that need to withstand the elements and protect those within. Being corrosion resistant, non-combustible, architecturally appealing, their outstanding list of benefits just can’t be beaten.