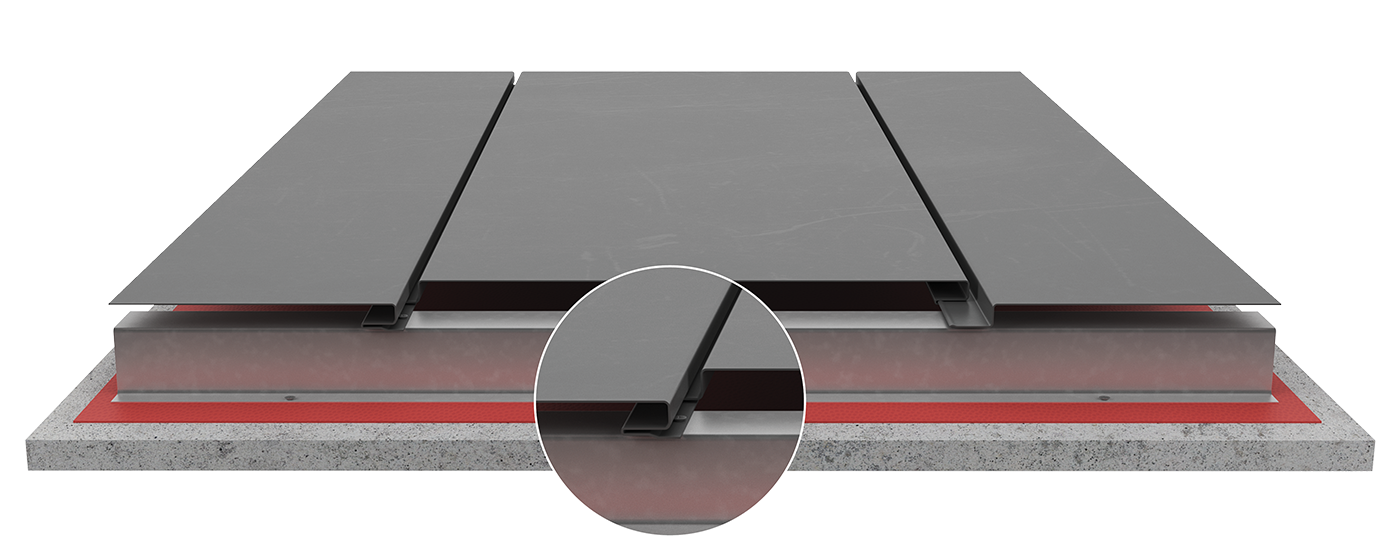

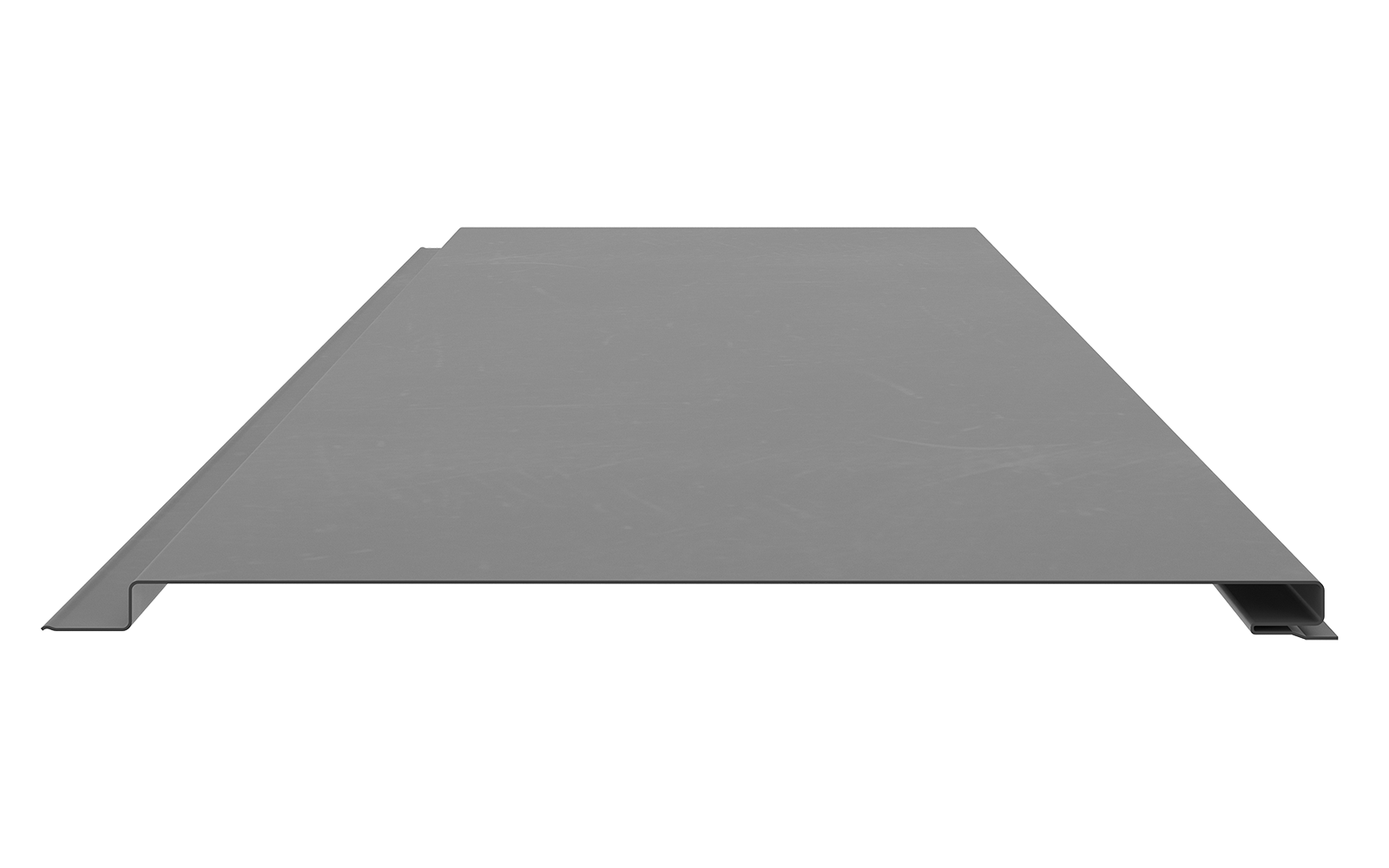

Provides a smooth looking system, flat appearance with negative details.

Natural ventilated air flow.

Solid panel design, installed directly on to a galvanised top hat and fixed directly onto the structural element of the building.

Fully waterproof without the use of exposed mastics and sealants. It is classified as a rain screen system allowing water to flow without entering the aluminium, zinc, corten, and copper wall panel structure.

Flexibility in overall appearance of the system as joints can vary from 0 – 18mm. The panels are adaptable in width to exactly fit the opening.

Economical as it creates minimum wastage of materials.

We work closely with architects during the design stages to share our expertise on installation and technical details. From traditional to contemporary applications, our aluminium, zinc and copper roofing and cladding solutions are specified based on their durable, sustainable and virtually maintenance-free nature that need to withstand the elements and protect those within. Being corrosion resistant, non-combustible, architecturally appealing, their outstanding list of benefits just can’t be beaten.