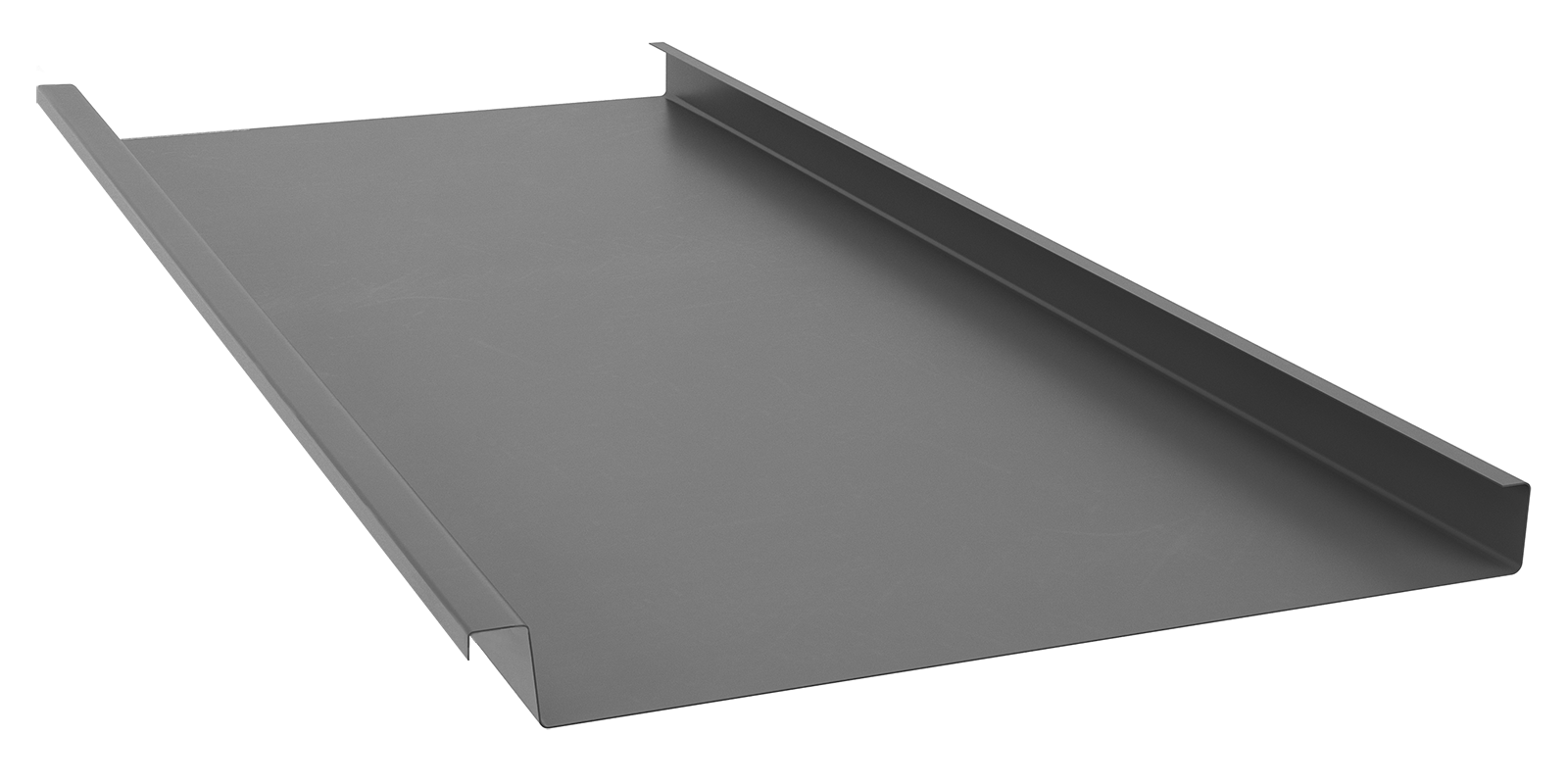

Standing seam system is a traditional flat-tray roofing and cladding system with a raised 25mm seam. All fixings are concealed using stainless steel clips that allow for expansion and contraction in the cladding panels. The pan widths are customisable using our state of the art manufacturing equipment to the millimetre allowing total control over your designs. It reflects the individual concerns for both light and shadow and produces designs that have a modern yet historical perspective that offers a traditional, refined look, with maximum flexibility. Standing Seam is capable of achieving intricate designs that other systems cannot. It is suitable for both roof (double-lock) and wall cladding (single-lock) which makes it ideal for dramatic residential and commercial architectural roofs and facades.