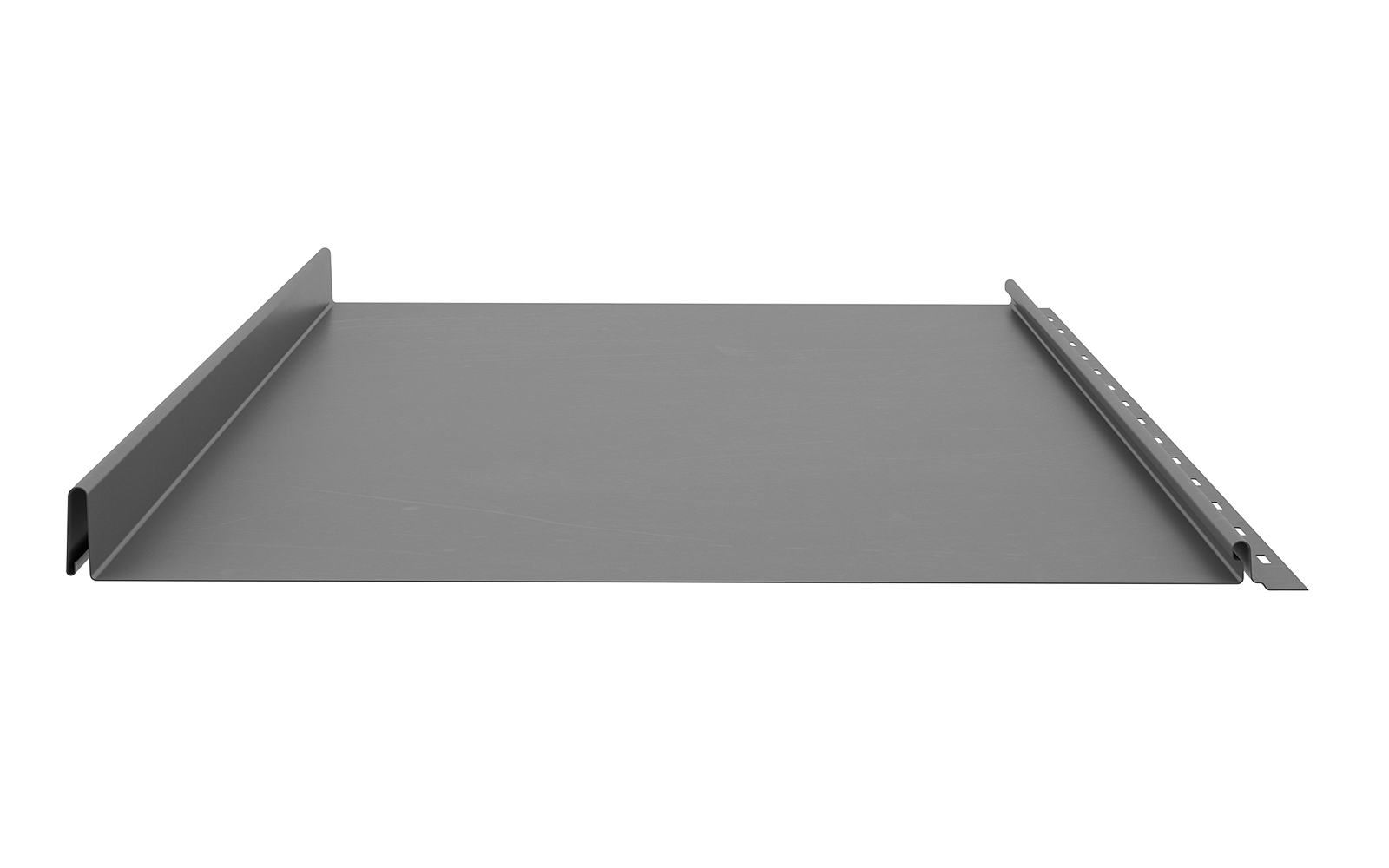

Nailstrip’s contemporary profile is well suited to modern architectural developments. Similar in appearance to Standing Seam and Snaplock, Nailstrip’s simplified installation method doesn’t require specialist tools – making it a popular alternative for installers and builders who don’t have access to Standing Seam seam closing equipment. Nailstrip panels are designed to “snap” together, offering low fuss installation.

No clips are required for the Nailstrip system. The pan widths can be customised if required using our state of the art manufacturing equipment. Nailstrip is available in 25mm raised seam and 38mm raised seam.