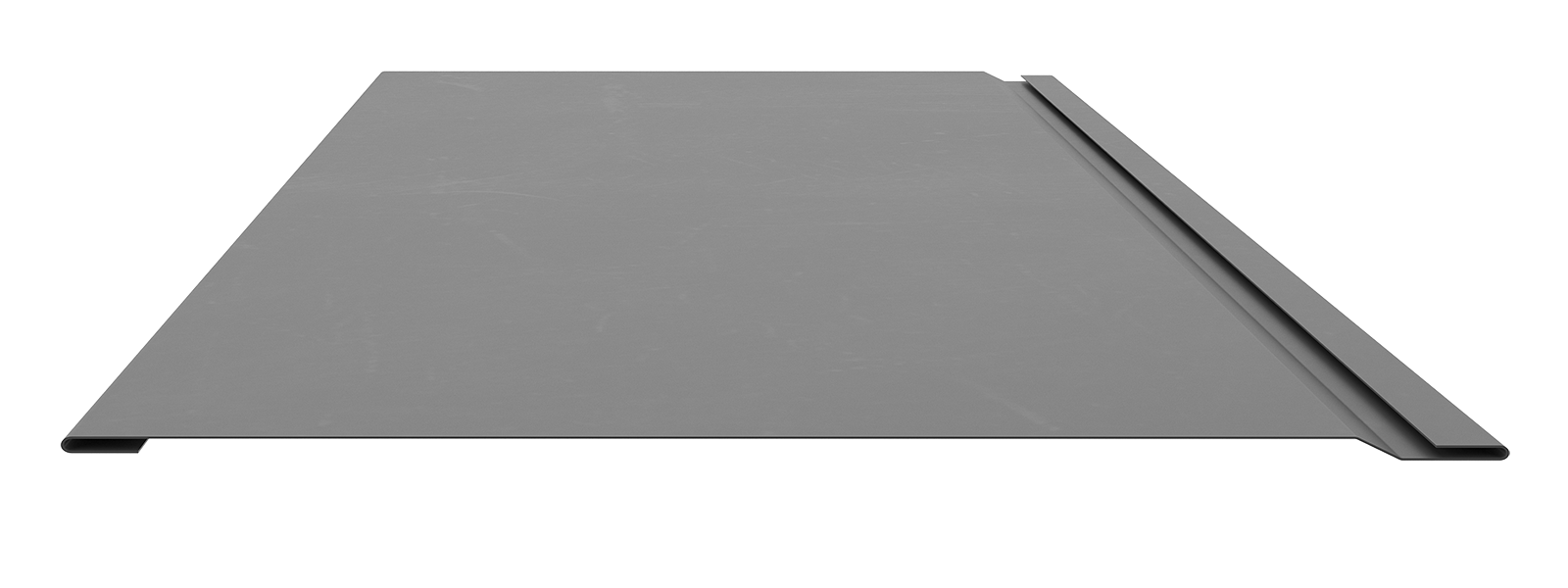

Flatlock offers an aesthetic unlike any other sheet metal profile. The panels lock together, creating a flush, flexible and thin facade. Flatlock shares its profile design with the Shingle system, and is also available in Reversed Flatlock, when deeper express lines are sought. The system uses a simple interlocking fold on all four sides.

Standard panel widths are 330mm for Aluminium or Colorbond and 430mm for Zinc. These are designed to reduce waste due to the coil widths (wider panels are available but may result in distortion or oil-canning).

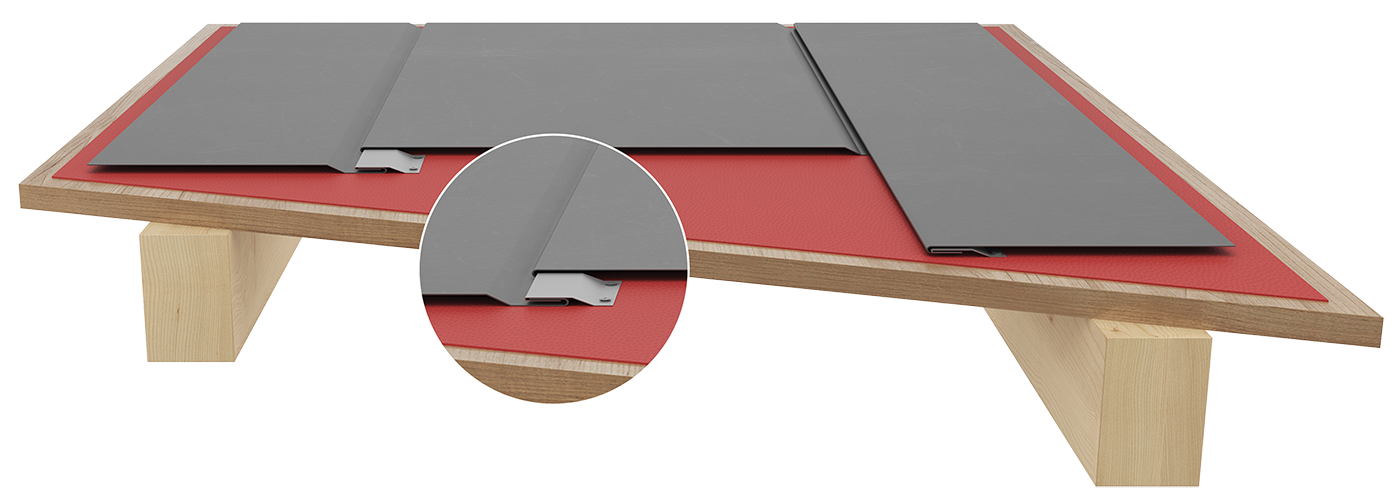

Flat-lock Panel is a wall system based on factory formed panels that are custom sized into rectangular, square or diamond shapes featuring a formed interlocking welt at all edges. They are installed by engaging the lower edge of each panel in the upper edge of the panel below and mechanically attaching the panels to supports using concealed clips located under the upper edges of panels.

The system includes a full range of factory formed clips, fasteners, flashings and finishing elements. The distance between the concealed clips are determined by the wind loading usually for residential buildings they are spaced at 300mm centres.

All Flat-lock and Recessed Flatlock applications must use a construction grade substrate. When working with zinc, on wall cladding applications a 20 mm continuous ventilation gap beneath the substrate, and a 40 mm gap on roof installations, must be allocated (note this is for zinc only). The substrate should be wrapped in a waterproofing membrane before cladding panels are laid.